Nonwovens

What are Nonwoven Fabrics?

Nonwoven fabrics are defined as a web or sheet of fibers bonded together by entangling fiber or filaments mechanically, thermally or chemically. They are flat, porous sheets that are made directly from separate fibers. They are not made by weaving or knitting and do not require converting the fibers to yarn.

Nonwoven fabrics are defined as a web or sheet of fibers bonded together by entangling fiber or filaments mechanically, thermally or chemically. They are flat, porous sheets that are made directly from separate fibers. They are not made by weaving or knitting and do not require converting the fibers to yarn.

Nonwoven fabrics have replaced many traditional textiles due to superior properties and efficient manufacturing processes. Most nonwovens can be effectively produced and finished to have specific benefits such as flame retardancy, high liquid absorbency, liquid repellency, high tensile strength, bacterial resistance, abrasion resistance, softness and more.

Nonwovens are engineered for disposable, reusable and permanent applications. Nonwovens are a part of many items we use every day. Furniture, mattresses, airplanes,automobiles, vacuum filters, and clothing are just some of the applications we are exposed to on a regular basis.

Common Production Methods include:

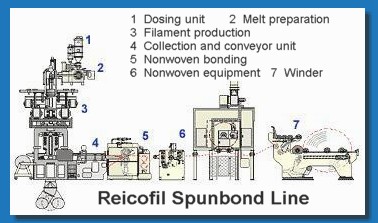

- Spunbond. Polymer chips are introduced into an extruder which produces continuous filaments that are cooled and stretched to give them strength. The filaments are then laid on a moving belt to form a web that is then thermally bonded between two temperature controlled steel rolls. Some bonding rolls have a pattern that is embossed into the web. Spunbonds are typically made from homopolymers such as polypropylene, polyester, polyethylene, or nylon. Some spunbonds are made from two polymer families creating a bi-component fabric.

- Spunlaced Nonwovens. Baled staple fiber is introduced to a carding machine to create a batt. The batt of unbonded fibers is then transferred via a mesh conveyor or perforated cylinders where it is processed through a high pressure water system that entangles the fibers to create the finished product. Fibers blends and finishes can vary depending on desired properties.

- Needlepunch Nonwovens. Baled staple fibers are introduced to a carding machine that distributes the fibers based on the desired basis weight. The batt of fiber is then needled by an oscillating needle board. The fibers are mechanically bonded by barbed needles entangling the fibers. The density of the fabric is controlled by the number of needle boards used.